Products >> Aluminum facade panel >>

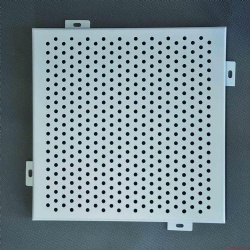

aluminum sunshade and screen

- Product No.:2023102483058

- Material:aluminum alloy sheet

- Coating finish:PVDf (option:powder coating)

- process method:laser cutted & peforated

- application area:ouddoor wall and sunshade)

- package:bubble film

There are currently two ways to produce aluminum sunshade and shading,

Previous Product:aluminum Wood grain ceiling square tube

Next Product:aluminum veneer panels for curtain wall system

Products Category

Contact Us

Name: Bob Fu

Tel: 18526561037

Mobile: +86-18526561037

E-mail: tech@aluminumartworks.com

WeChat: +8613020888816

Whatsapp: +8613020888816

Add: Lutai Economic Development Zone, Ninghe District, Tianjin, 30016, China.

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry