how to make aluminum honeycomb panel, why it is so strong?

Manufacturing aluminum honeycomb panels involves several steps, and these panels are known for their strength-to-weight ratio, making them suitable for various applications in industries such as aerospace, automotive, construction, and marine. Here's a general overview of the manufacturing process and the factors contributing to their strength:

Manufacturing Process:

-

Materials:

- Aluminum Sheets: The process starts with flat aluminum sheets.

- Adhesive:

- A layer of adhesive is applied to the aluminum sheets.

-

Corrugation:

- The adhesive-coated sheets are corrugated, creating a series of alternating flat and corrugated sheets.

-

Bonding:

- The corrugated sheets are bonded together using heat and pressure, with the adhesive creating a strong bond between them.

-

Expanding:

- The bonded sheets are then expanded, creating the characteristic honeycomb structure.

-

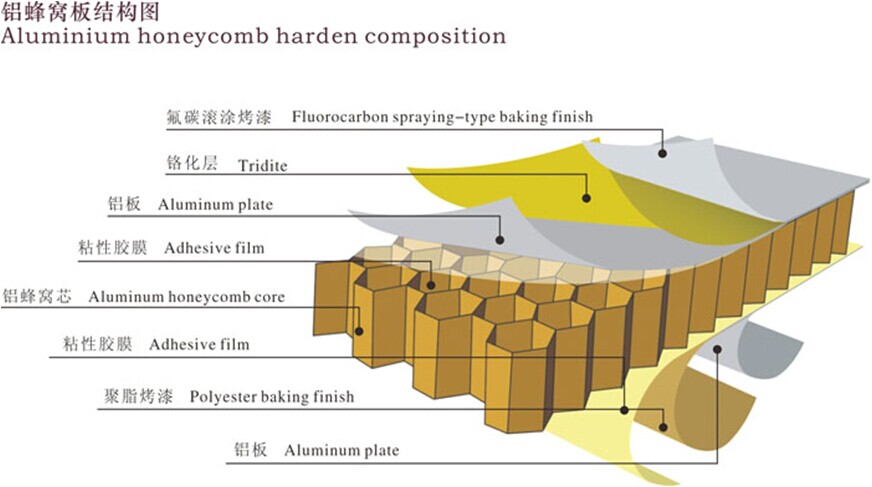

Facing:

- Additional sheets may be added to the top and bottom of the honeycomb core, serving as facing materials. These facing sheets contribute to the panel's overall strength.

-

Cutting:

- The panels are cut to the desired size.

Strength Characteristics:

-

Honeycomb Structure:

- The hexagonal honeycomb structure provides excellent strength due to its geometric efficiency. It distributes loads evenly across the panel.

- The honeycomb structure also minimizes material usage without sacrificing strength.

-

High Strength-to-Weight Ratio:

- Aluminum itself is relatively lightweight compared to other metals, and the honeycomb structure enhances its strength without significantly increasing its weight.

-

Rigidity and Stiffness:

- The honeycomb structure provides high rigidity and stiffness, making the panels resistant to bending and deformation.

-

Impact Resistance:

- The design of the honeycomb structure absorbs and disperses impact energy, making the panels highly resistant to damage from impacts.

-

Compression and Shear Strength:

- The bonded and corrugated structure enhances the compression and shear strength of the panel.

-

Lightweight:

- The combination of aluminum and the honeycomb structure results in a lightweight material, making it suitable for applications where weight is a critical factor.

-

Versatility:

- Aluminum honeycomb panels can be customized for various applications by adjusting the thickness, cell size, and facing materials.

In summary, the strength of aluminum honeycomb panels is a result of the combination of the inherent properties of aluminum, the geometric efficiency of the honeycomb structure, and the bonding process used during manufacturing. These factors collectively contribute to a material that is strong, lightweight, and versatile

Latest News

Contact Us

Name: Bob Fu

Tel: 18526561037

Mobile: +86-18526561037

E-mail: tech@aluminumartworks.com

WeChat: +8613020888816

Whatsapp: +8613020888816

Add: Lutai Economic Development Zone, Ninghe District, Tianjin, 30016, China.

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry